Piston

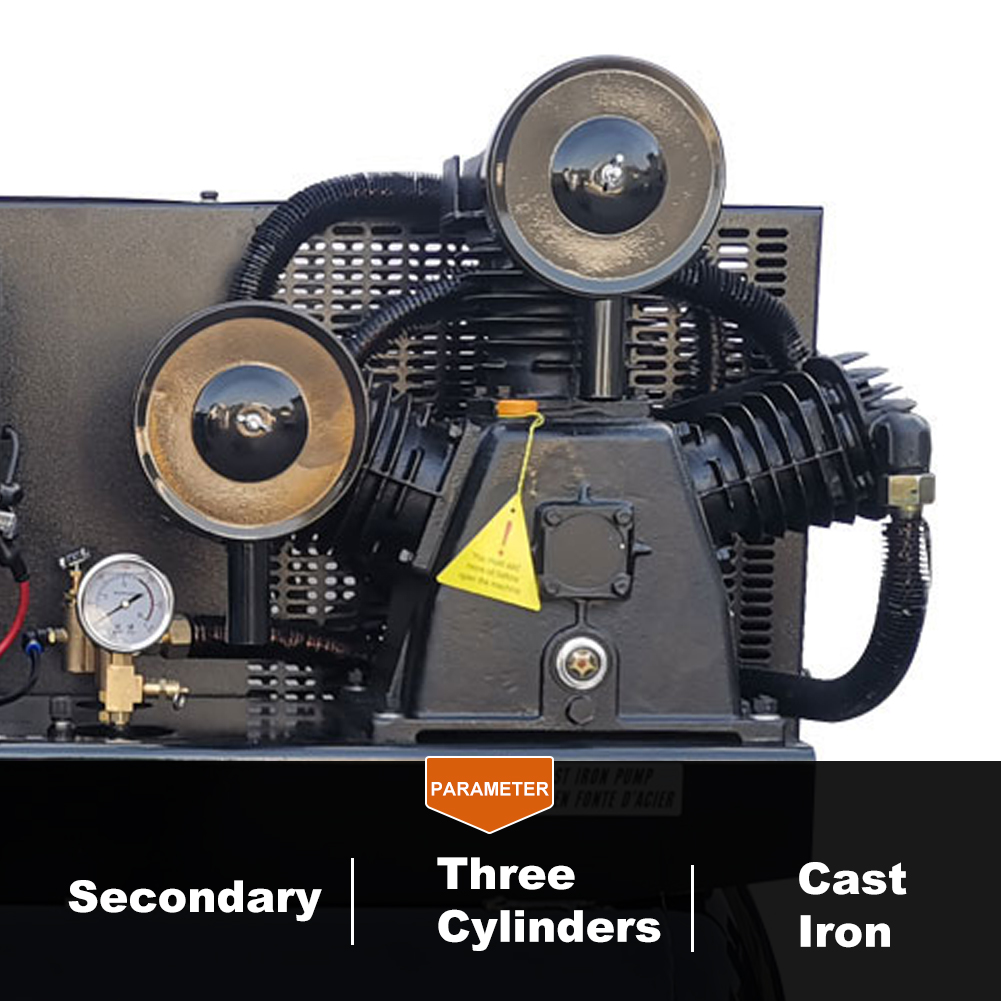

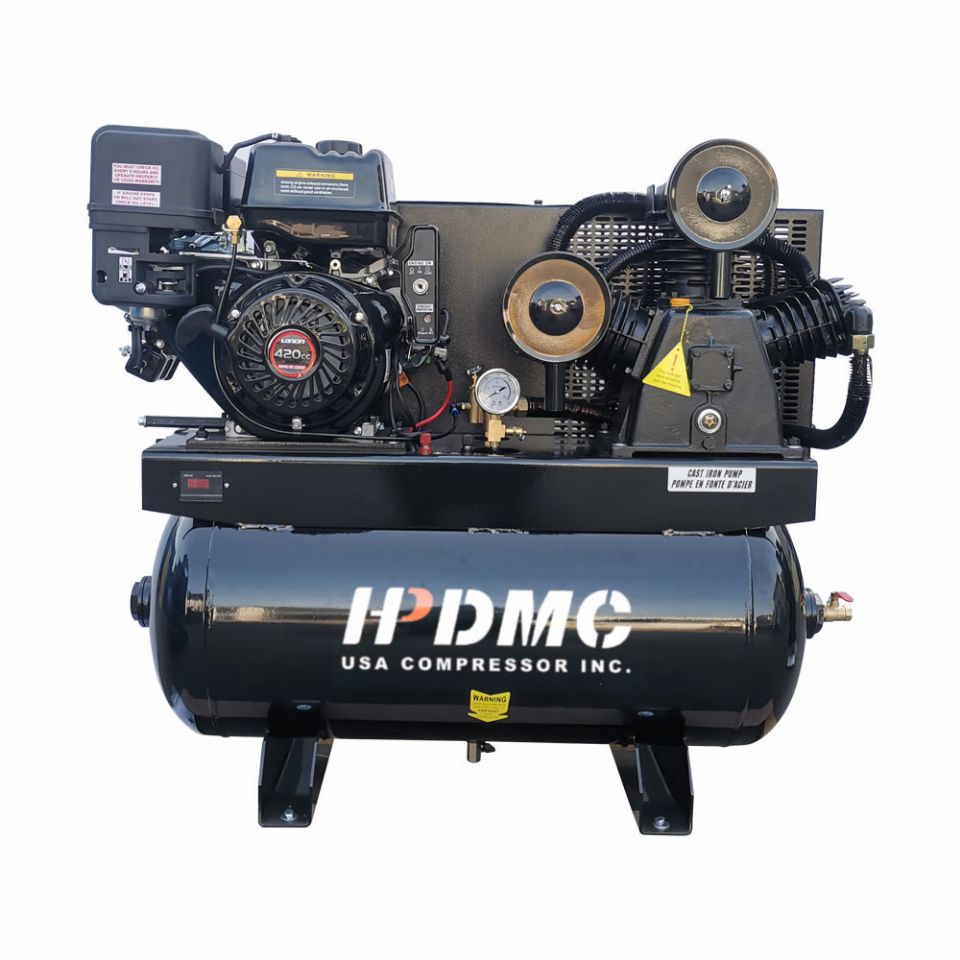

Piston air compressors are the most commonly used industrial air compressors, operating on displacement principles to increase the pressure of enclosed air. They utilize a valve system with two stainless steel discs: as the piston moves downward, the largest disc folds, allowing air to enter the cylinder. When the piston moves upward, the disc seals against the valve seat, compressing the air, which is then forced through an opening in the seat and delivered to the end process.

Key advantages of piston compressors include affordability, low maintenance, and easy access to spare and replacement parts. However, they tend to produce more noise and heat and have a higher risk of oil contamination in the compressed air.

Sort by

Latest

Stay in the loop with HPDMC

© 2025 Bravo Equipment Corporation All Rights Reserved. Friendly Links: Davyenergy ; DBC ; Auto-Hydra ; LiveShelf